Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

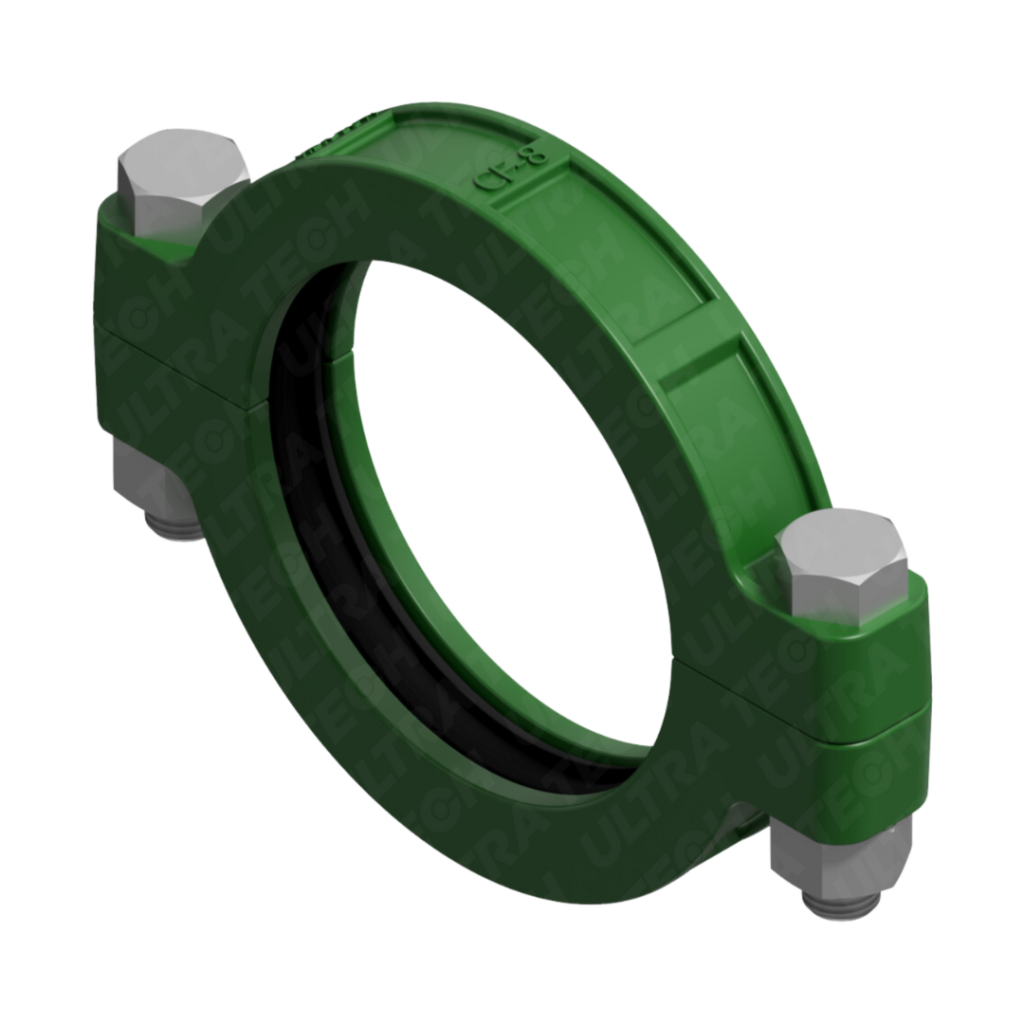

ULTRA DUTY

8” HIGH PRESSURE

FORGED COUPLING

Couplings join two pieces of pipe together. Ultra Tech Hevi-Duty 2 Bolt Coupling assemblies consists of two-piece ductile iron casting, captive rubber gasket, nuts and bolts to secure the coupling halves together.

SUPER HIGH PRESSURE

HIGH PRESSURE

Paste Systems:

Water / Sludge Systems:

STANDARD HEVI-DUTY

Ultra Tech flanges secure two pipes together using bolted connections.

Flanges are the most common end-style and a great solution for field-installs already using Flange connections. Ultra Tech flange sizes range from 2.5” to 24” (63.6mm to 609.6mm)

Meets ASME B16.5 standards

STANDARD FLANGES:

STANDARD ROTATING FLANGES:

CUSTOM:

Custom flanges available. Consult factory for details.

Permanent steel ring connections can easily be field-welded which provides a rigid fit. Made from mild steel specially designed to prevent heat treat loss at joint connection.

Rings are designed for vertical loads and pressure applications.

Conventional

Self-Aligning Weld Rings

Common Applications: Boreholes, Dredges, Offsets (S-bends)

Cut grooves on the outer diameter of the pipe. They are used in conjunction with couplings for rigid or flexible connections. This connection is dependent on the coupling style.

Cut Grooves are available in multiple styles:

Grooves can be added to nominal pipe sizes 2.5″ up to 20″ (63.5mm – 508mm). Coupling dictates groove style used. Consult factory with details.

D-Rings:

Slip-on style ring with specified groove to prevent cutting into pipe wall. This prolongs the life of the pipe. Requires coupling the next size up.