Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

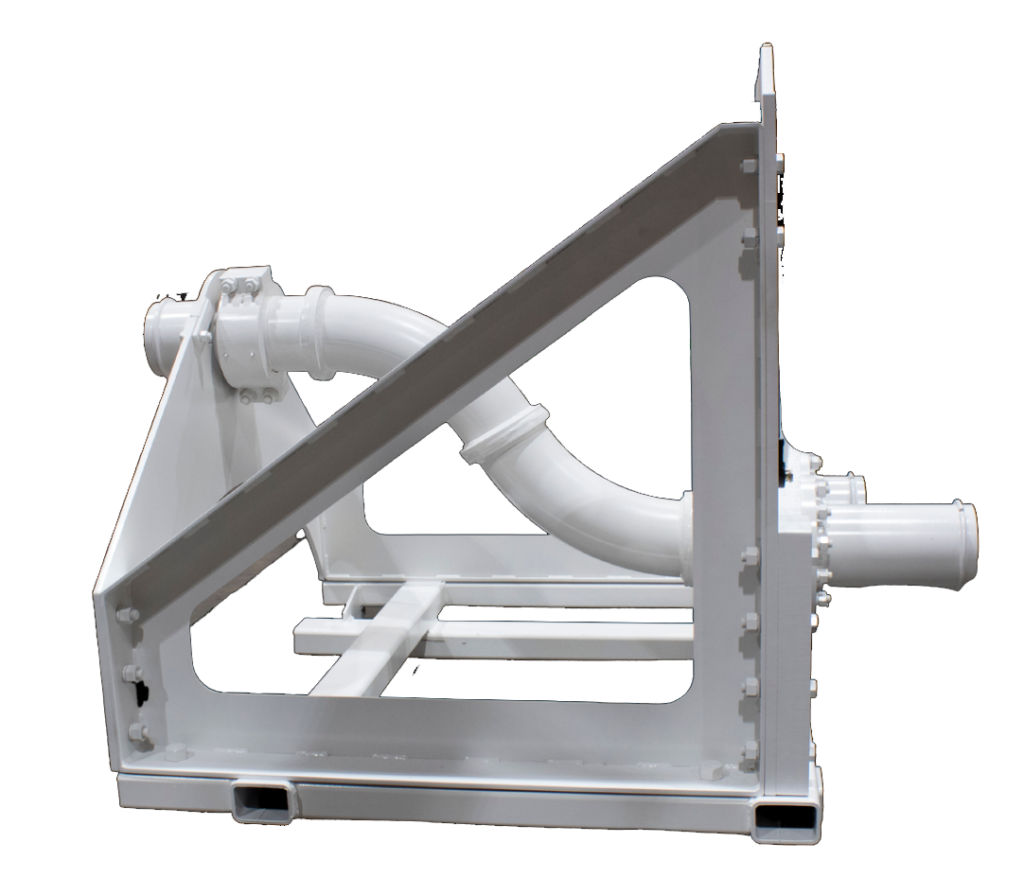

The hydraulically operated Ultra Tech Diversion Valve is designed for rugged use in mining or similar bulk transport applications like abrasive slurry. Applications include paste back fill, hydraulic tailings and other systems where multi-line outlet with single inlet is the operating mode. Ultra Tech Diversion Valve applications include pneumatic and hydraulic piping systems for extremely abrasive materials such as mine tailings, sand reclamation systems, dredge outlet lines, bottom ash, fly ash and pulverized coal.