Ultra Tech offers a threaded end-style option for our induction hardened pipe that results in faster installation, less downtime, and longer life. Ultra Tech’s threaded pipe can save you thousands by dramatically reducing install time. Our threaded pipelines provide high abrasion resistance and seamless transition points that will extend the life of your system.

Transcript: Ultra Tech Threaded Pipe

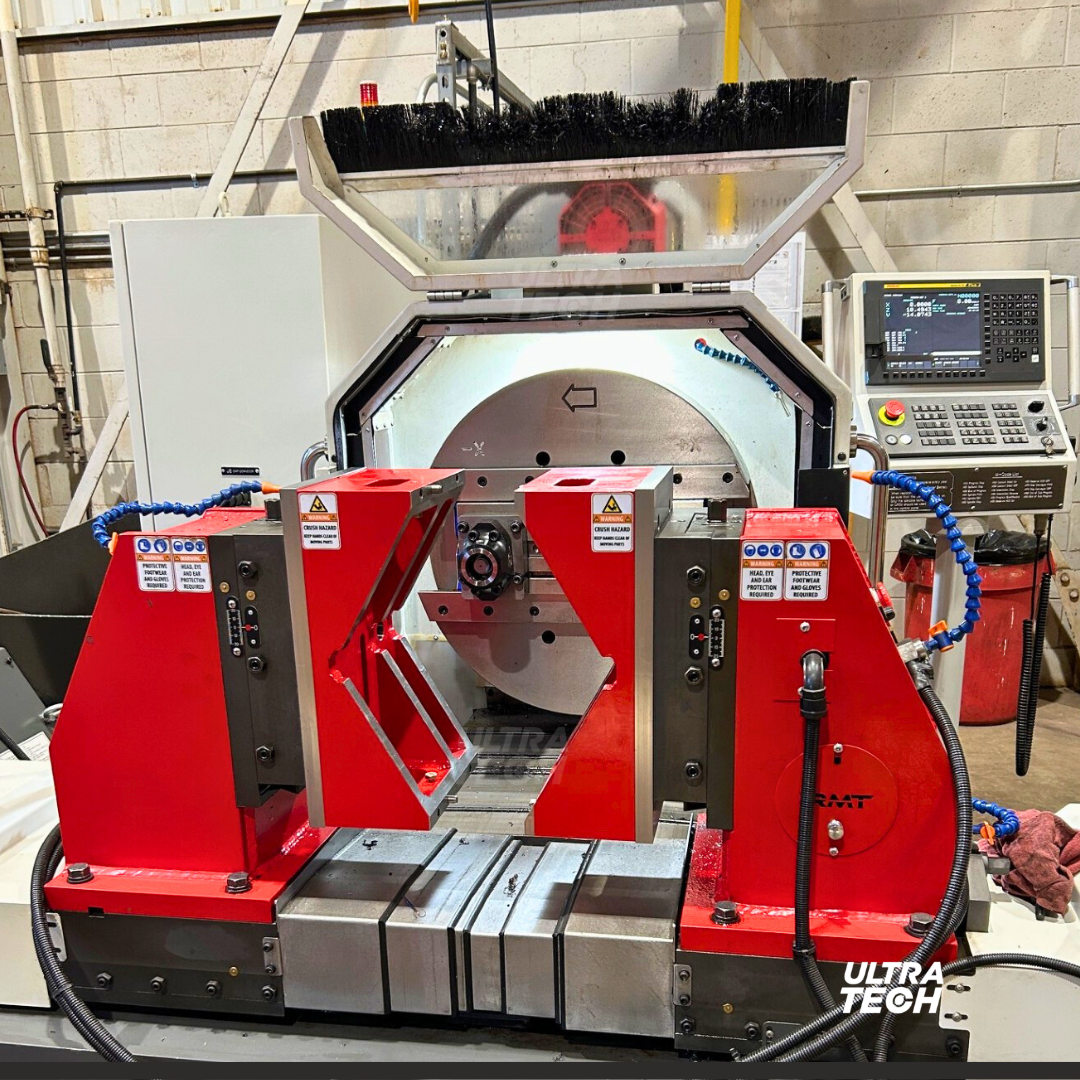

Are you interested in borehole or vertical applications? It is not a pipe dream anymore. Ultra Tech offers a threaded option for our induction hardened pipes, which results in faster installation, less downtime, and longer life. Ultra Tech can save you thousands by dramatically reducing install time with seamless transition points and extending the life of your pipe.

In the past, pipes were welded together vertically requiring a lot of man-hours in fitting the pipe and suspending the pipe in potentially dangerous situations. Let’s talk about why you need Ultra Tech pipe. Do you have abrasive slurry on the move? You need to toughen up your pipe. With Ultra Tech, you get piping that is formed by proprietary steel chemistry and specific induction hardening to give you increased tensile strength up to 90 K. This allows the pipe to wear down thinner at higher pressures without bursting. It means your pipe remains ductile outside while hardened on the inside surface. Ultra Tech pipe allows for in-field cutting and welding for fitment, making installation easier.

Here is the math for a sample borehole installation. In this example the mine can drill a smaller hole, reducing the time and money on drilling. Installation requires less personnel and no weld inspection. Threaded pipe takes less than half the time to install. You save on installation costs and downtime. With potential savings of $400,000 in this example.

Ultra Tech pipe is deployed globally with installations in the Americas, Europe, the Middle East, and Asia. You can find yours here. Ultra Tech Pipe – longer life and less downtime mean saving your company money.