Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

Download this white paper to learn how the most influential mining companies reduce their carbon footprint from pipe by up to 80%. View now.

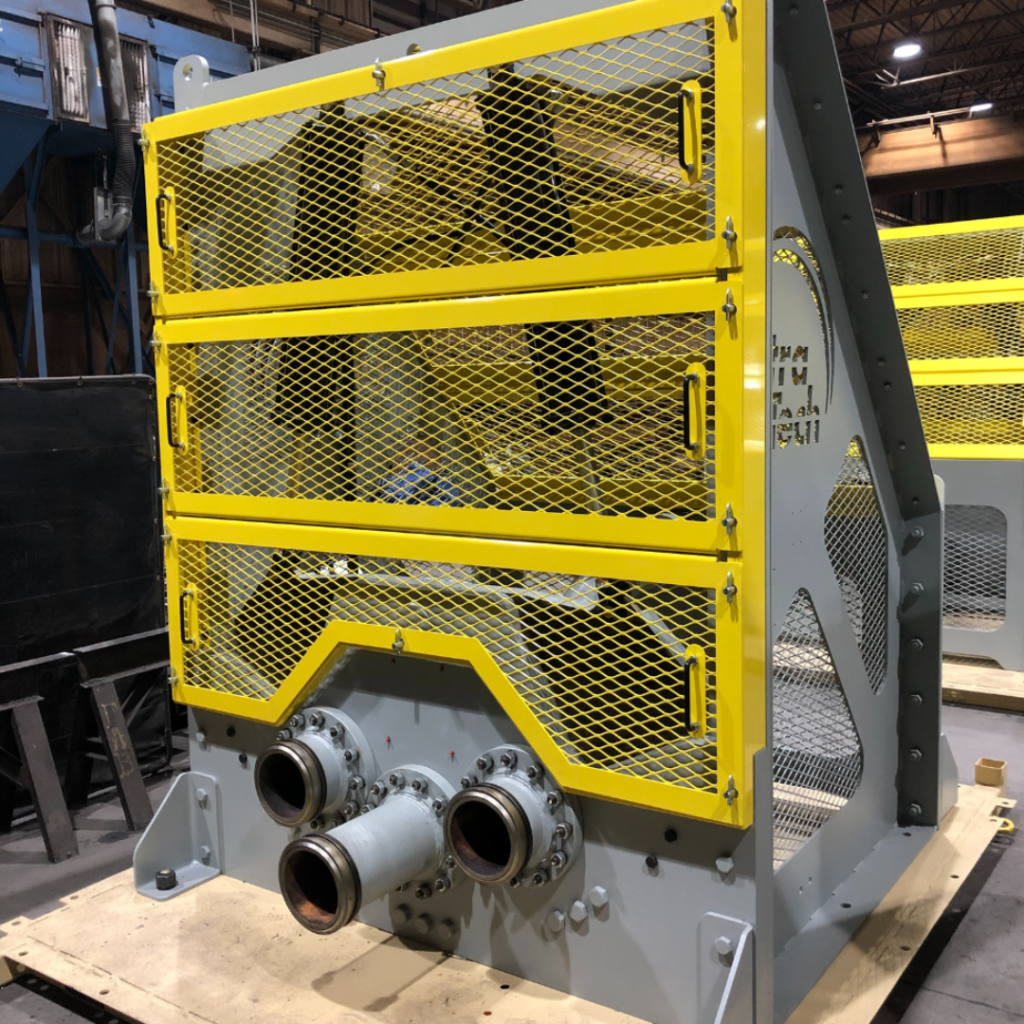

The combination of impact and abrasion from truck or loader dumps into your primary crushing systems presents a unique and challenging environment that is perfect for a Tri-Braze solution. No other wear steel is built to handle this level of impact without cracking, while maintaining the hardness to stay in service for extended periods between maintenance cycles.

The safe and effective movement of tailings after the ore is extracted is a vital part of a mining operation. Pushing washed material away from your crushing and sorting equipment can be a difficult process; sometimes requiring miles of reliable, durable pipe. With over 30 years of proven success in long-distance, hydraulic tailings applications, our engineering team can assist in the design of new systems or help to make your existing tailings pipeline more reliable and efficient.

Learn how a power plant used Tricon wear solutions to improve productivity and reduce stoppage time.