In mining, industrial processing, and heavy-duty material transport, controlling the flow of abrasive media is more than a design challenge—it’s a performance imperative. Ultra Tech’s abrasion-resistant pipe systems are purpose-built to meet this challenge head-on, offering a full suite of induction-hardened pipes, bends, and fittings that deliver superior wear resistance and optimized flow dynamics.

Precision Flow Control with Engineered Geometry

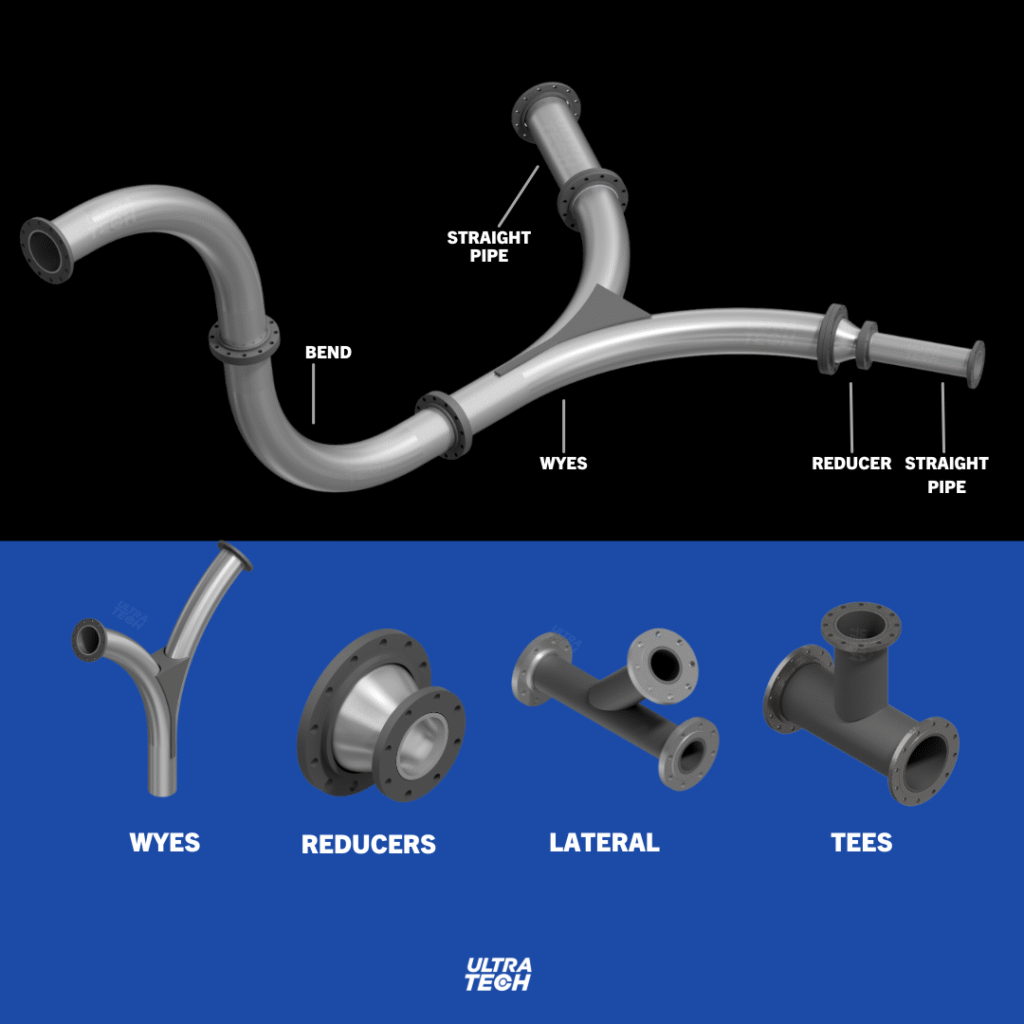

Ultra Tech’s product line goes beyond straight pipe sections. Our custom-engineered bends, elbows, reducers, and transitions are designed to manage directional changes and flow velocity, reducing turbulence and minimizing wear at high-impact zones. This is especially critical in systems handling slurry, tailings, concrete, ash, or other abrasive materials, where uncontrolled flow can lead to premature failure and costly downtime.

Built for the Harshest Conditions

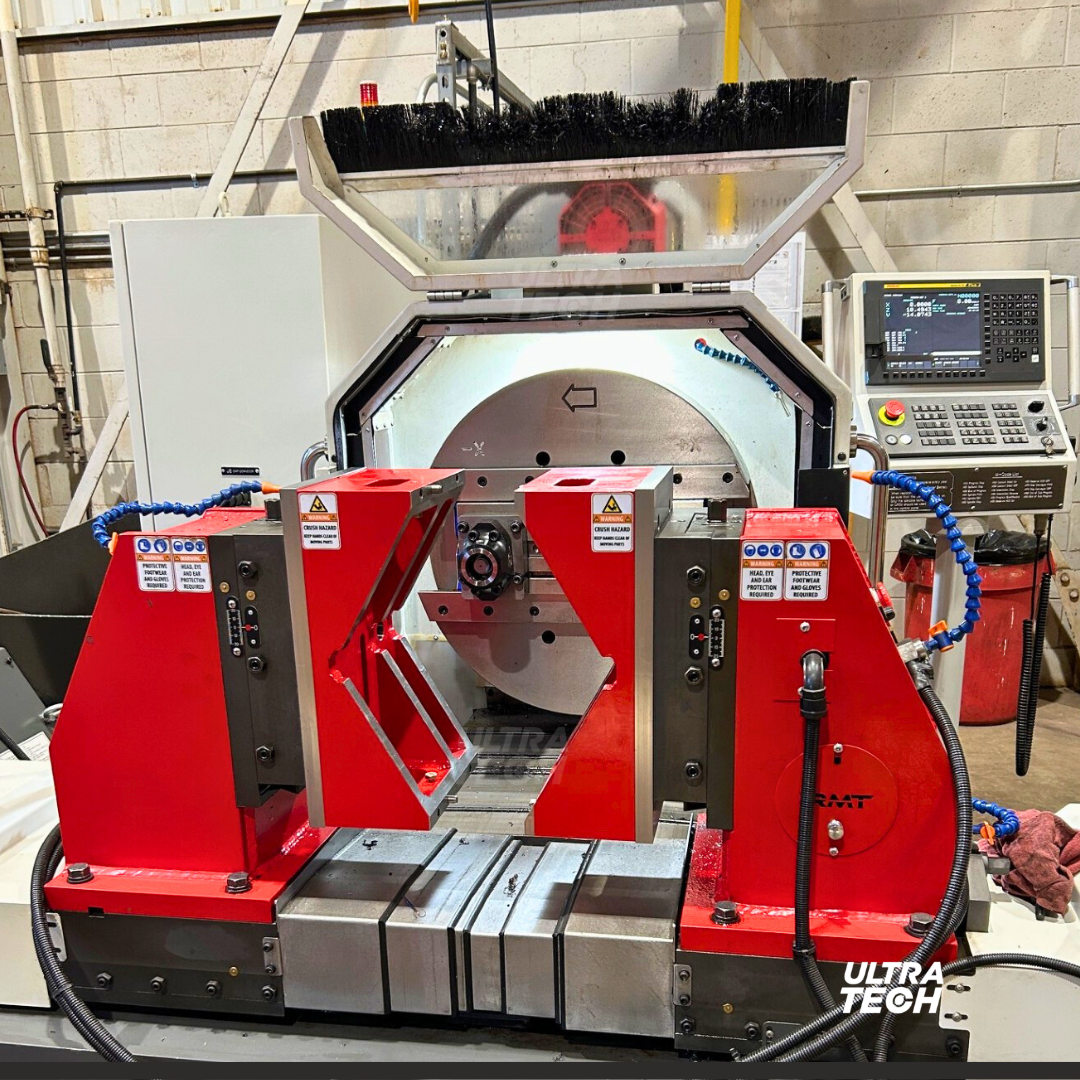

Each component is manufactured using Ultra Tech’s proprietary induction hardening process, achieving a tapered hardness profile that withstand extreme abrasion. The result is a system that not only lasts longer but also maintains consistent performance under pressure.

From Specification to Validation—A True Engineering Partner

Ultra Tech doesn’t just supply pipe systems—they support engineering teams from bid package development through delivery and field validation. Whether you’re designing a new pipeline or upgrading an existing one, Ultra Tech provides:

- Technical consultation and spec support

- Custom configurations to fit complex layouts

- Proven performance data to support design decisions

Applications Include:

- Mining slurry and tailings transport

- Industrial waste and ash handling

- Concrete pumping systems

- Pneumatic and hydraulic material conveyance